Bonding principle of Bi/Sn/Au solder joints

Achieving high quality

fluxless solder joint in air ambient

Developing fluxless lead

free FCOF (flip chip on flex)

technology

Flip

chip packaging for high temperature and power devices

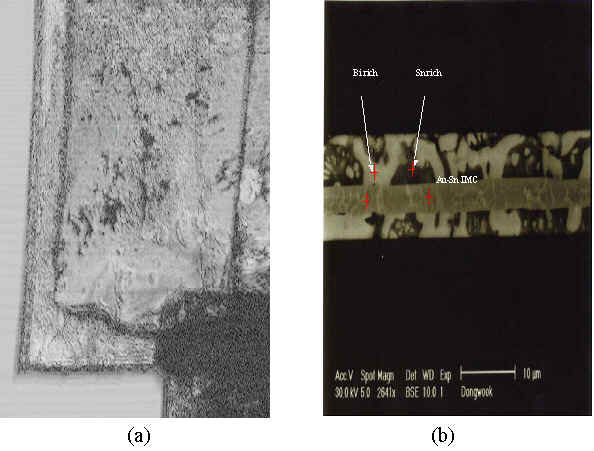

Solder joints and Microstructure of Bi/Sn/Au

(a)

SAM acoustic image

of a Bi/Sn/Au solder joint

(b)

SEM image

of Bi/Sn/Au solder joint

Our

lab has transmission mode Scanning Acoustic Microscopy. Resolution: up

to 10micrometer

Fluxless tin rich Au-Sn flip chip bonding process

1.

Formation of Cr/Au pad

2. Formation of solder bumps through stencil mask on Si wafer

3. Chip mounting and joint formation in H2 ambient

Solder

bump formation

(a)

(b)

(a)

Multilayer tin rich eutectic Au-Sn bump after deposition

(b)

The tin rich eutectic Au-Sn solder bump after re-flow in hydrogen